Understanding the Elaborated Process of Recycling PET Bottles

- September 6, 2023

- Posted by: Kishan Pindoliya

- Category: Business, Plans

Reducing plastic waste and finding sustainable ways to manage plastic waste is a pressing issue in today’s world. While it is challenging to eliminate plastic waste entirely from our lives. However, the world continues to take various actions against the global environmental impact of plastics. However, many companies are revising their operation to implement sustainable practices. Recycling is the key strategy to mitigate the environmental impact.

PET( Polyethylene Terephthalate) is a common type of plastic used in the production of water, Milk Jug and soda bottles as well as various packaging materials. When you look at the bottom of a plastic bottle, you might indeed see a triangular symbol with a number in the middle. This number represents the resin identification code, indicating the type of plastic. For PET bottles you will typically find “1” inside the triangle.

While many people are familiar with the concept of recycling, few are familiar with the exact process involved. Recycling pet bottles helps in decreasing waste and preserving resources, as well as promoting a more environmentally conscious and sustainable lifestyle.

PET Bottle Recycling Process

Although the PET bottle recycling procedure is complicated, it is important to recycle these bottles whenever possible. PET bottles can be recycled into new products such as bottles, clothing, carpeting, and furniture. Recycling PET bottles contributes to pollution reduction and resource conservation.

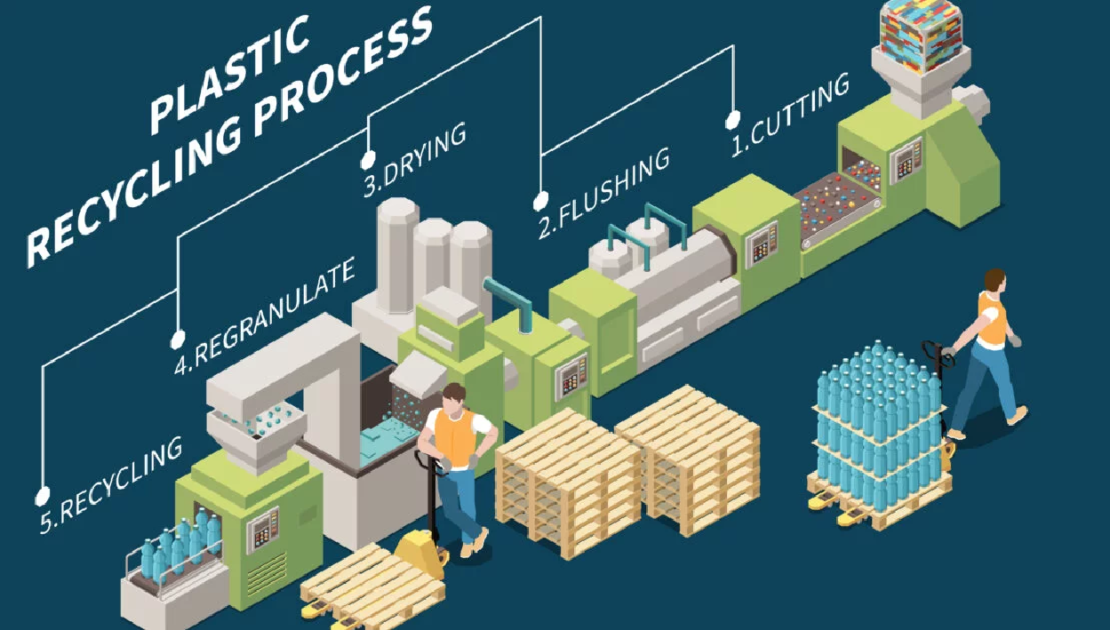

Understanding the elaborate process behind PET recycling involves several steps

Collection

The Recycling company collects the PET bottles through various channels like Recycle bins, drop-off centres, and curbside pickups. These bottles are typically sorted at facilities. Collecting PET bottles for recycling is important because the capacity for recycling is more than being used. Every year around 11 billion PET bottles end up being burned and buried in landfills instead of being recycled. This means we have a big opportunity to reduce waste and environmental harm by simply collecting and recycling more PET bottles.

Sorting

At recycling facilities, the collected bottles are sorted into separate PET bottles from other plastics and contaminants. Automated machines and manual labour are often used for this step. This is because the presence of the plastic bottle would contaminate the PET recycling process, limiting its quality for reuse, reducing efficiency and contributing to waste. This makes sorting a long process as many people do not toss away trash in the right bin.

Flushing

The sorted PET bottles undergo a flushing process to remove labels, caps, and any remaining liquids or contaminants. This is done using a variety of methods, including water jets, detergents, and air knives. This is an important step to ensure that the recycled PET is free of contaminants that could damage the equipment or degrade the quality of the recycled product. Thorough cleaning is essential for producing high-quality recycled PET (rPET).

Shredding

Post-flushing, the bottles are fed into large machines that shred them into tiny, consistent pieces or flakes with the use of revolving blades or hammers. These shreds are then washed to remove any remaining contaminants. After that, the flakes are dried to remove any remaining moisture. Shredding increases the surface area of the material, making it easier to process.

Melt and Purify

The shredded PET flakes are then heated and melted. This molten PET can be further purified to remove any impurities or residual. This is done with the help of a machine called an extruder. The extruder heats the flakes and then forces them through a die, which gives them the desired shape. This step is essential in maintaining the purity of recycled PET material.

Colouring and Incorporating Additives.

The new form may be coloured or contain additional additions. This is determined by the finished product. If recycled PET is used to manufacture a new bottle, for example, it may be coloured to match the original bottle.

Forming and Moulding

Once melted, the plastic is carefully formed into new shapes using various processes such as injection moulding or blow moulding. Injection moulding involves pumping molten plastic into moulds, whereas blow moulding uses air to inflate the plastic into the required shape. These methods enable the production of a wide range of products, including packing containers, furniture, apparel, and even car parts.

After that, the new form is moulded or made into the desired product. This could be a bottle, a piece of plastic, or something else. Following that, the moulded or formed product is tested to ensure that it fulfils quality standards.

Quality Assurance

The quality control procedure includes thorough inspections and tests to detect any flaws or inconsistencies in the recycled plastic items. Qualified specialists extensively inspect each item, looking for flaws such as cracks, malformed pieces, or incorrect dimensions. They also ensure that the material composition fulfils the required specifications. Hence, Quality control methods are in place throughout the recycling process to guarantee that the recycled PET satisfies the needed standards for strength, purity, and safety.

Demand in the Market

The successful recycling of PET bottles is dependent on the availability of recycled material. To develop a sustainable market, both manufacturers and consumers must promote the usage of recycled PET in products.

Usage of Recycled PET

Recycled plastic is commonly used in the production of new packaging materials. Bottles, containers, and bags are examples of these materials, which can be found at supermarkets, pharmacies, and other retail locations. Companies that use recycled plastic in packaging reduce their dependency on virgin resources while also reducing their environmental footprint.

The construction industry also makes use of recycled plastic. It can be transformed into materials including pipes, roofing tiles, and insulation, giving environmentally friendly alternatives to typical building materials. These goods not only help to save natural resources, but they also aid in improving building energy efficiency.

A Simple yet Effective Step

Educate and inform your community about the importance of pet bottle recycling, and encourage friends and family to join the sustainable cause. Support for recycling-friendly regulations at the local level, and promote more effective waste management systems.

Pet bottle recycling has numerous advantages and is extremely important in our culture. We can help the environment by actively participating in the recycling process, which conserves natural resources, reduces waste, and promotes sustainable behaviours. Let us continue to explore the challenge of pet bottle recycling and work towards a brighter, more sustainable future.

How can we help

We are committed to addressing these issues and positively impacting the environment. As we’ve seen, recycling PET bottles isn’t simply a matter of convenience; it’s also an important step toward conserving natural resources, decreasing waste, and encouraging sustainable behaviours.

We know hot-washed PET flakes represent a great combination of excellence, purity, and environmental responsibility in the field of plastic recycling. Radhe Plastic Ltd takes great delight in offering these high-quality flakes, which are precisely sourced from post-consumer beverage bottles, assuring an environmentally sustainable approach and giving exceptional quality.Feel free to address your concerns.